High Precision: Sliding head lathes excel in making precision elements with tight geometric tolerances. The look of this machine kind permits intricate and complex machining operations to get done efficiently with small enter.

Picking TMC Technologies signifies deciding on a husband or wife who understands the nuances of high precision CNC lathe work. We’ve witnessed how the ideal machine could make all the real difference in initiatives requiring limited tolerances and complex parts.

The CNC lathe headstock transmits energy with the motor towards the workpiece, enabling specific rotation and motion for machining. It securely grips the workpiece and will allow variable speeds, facilitating the generation of intricate shapes.

The fundamental principle of turning has not improved For the reason that common lathe: A workpiece is rotated through the principle spindle as well as a reducing movement is generated by way of contact with a turning tool.

The CLX 450 TC is the entry-degree tool for turning and milling. The many designs of your CTX beta TC, CTX gamma TC and NTX collection also offer you an appropriate machine For each application During this region – whatever the fat from the workpieces. The Turn & Mill machines are Geared up with the compactMASTER milling spindle.

By comprehension the differences among set and sliding headstocks, brands could make informed decisions when selecting a CNC lathe machine that aligns with their specific machining objectives and creation prerequisites.

This set up is ideal for parts that involve machining on equally finishes. By making use of twin spindles, you may lower setup occasions and improve output fees.

Preserving good lubrication on the spindle bearings together with other relocating parts is crucial to scale back friction, warmth era, and dress in. A scheduled lubrication method needs to be carried out, following the producer’s tips.

Automation: These machines function with minimal human intervention, substantially cutting down labor expenditures and human error.

Price tag Discounts: Once the Original financial commitment Value, sliding head lathes can provide a speedy return on investment decision with major Charge cost savings over time because of their high performance, diminished product waste, and reduced running expenditures.

Star GB is the sole enterprise that are entirely dedicated to sliding head lathe know-how. Star machines are developed for the extremely-fashionable Kikugawa plant in Japan and so are renowned for their remarkable Make excellent, long-phrase dependability and Excellent functionality.

MDA Precision is dedicated to delivering only the highest high quality benchtop machining products and services. New benefit-added products are constantly being produced at MDA Precision for the benchtop machine tool marketplace.

At the center from the headstock is the main spindle, a cylindrical part click here that serves since the powerhouse from the machine.

We fully grasp the soreness points of sourcing trusted suppliers and making certain your machinery makes accurate and dependable benefits more than its lifespan.

Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Freddie Prinze Jr. Then & Now!

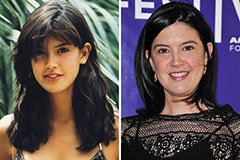

Freddie Prinze Jr. Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!